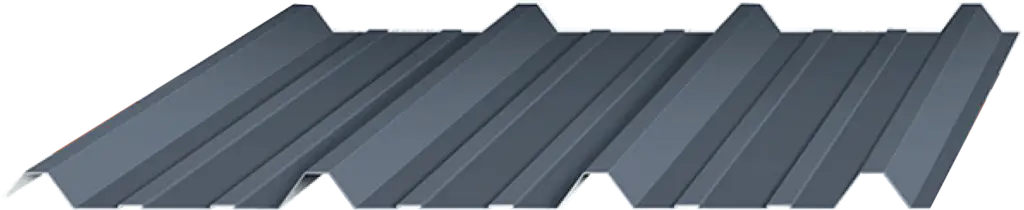

PBR Panel

Purlin Bearing Rib (PBR) panels are proven systems for both roofing and siding projects.

Home » Metal Panel Systems » Exposed Fastener Panels » PBR Panel

Purlin Bearing Rib

The PBR panel system is a great option for roofing and siding on a wide range of building projects including pre-engineered metal structures, post-frame buildings, and residential or commercial projects.

Recommended for commercial and industrial applications, as well as consumer-based projects, PBR Panels offer durability and reliability. Their adaptability makes them a preferred choice for a wide range of construction projects.

Designed to withstand the test of time, PBR Panels offer long-lasting performance, ensuring dependable protection for structures in diverse environments. Their durability makes them a practical choice for projects requiring resilience and sustainability.

PBR Panels come in a range of energy-efficient colors and paint systems, providing customization options to meet specific aesthetic preferences and energy efficiency goals. This versatility allows for seamless integration into various architectural styles.

The flexibility of PBR Panels extends to their compatibility with other building materials, offering opportunities for unique design combinations. Architects and builders can leverage PBR Panels to create striking and functional structures tailored to their vision and project requirements.

PBR panels are a practical and adaptable metal roofing and siding solution, suitable for a variety of applications. With its durability, energy-efficient options, and compatibility with other materials, the PBR panel is a useful asset in modern construction projects.

Panel Features

Panel Features Include:

- 26 gauge steel (standard)

- 29 gauge steel (optional)

- 24 gauge steel (optional)

- Substrate Materials:

- Galvalume (standard)

- Galvanized (optional)

- Colors available on standard, premium and metallic.

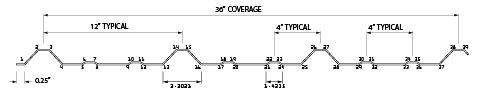

- Rib Spacing: 12″ O.C.

- Rib Height: 1.25”

Testing & Performance

Panel Certifications Include:

- UL Construction Numbers: TGKX.79, TGKX.104, TGKX.112, TGKX.161, TGKX.167,TGKX.184,TGKX.542.

- Uplift resistance of prepared roof-covering materials

- UL 580 Class90.

- Impact resistance of prepared roof-covering materials

- UL2218 Class 4.

- Fire tests of roof coverings

- UL 790.

- Class A, B, C. External fire exposure.

- TDI Texas Approved

Get a Quote

Panel Details

Panel Profile

Panel Enviroments

PBR Panel is suitable for use on the following environments:

- Extreme High Temperatures

- Low Temperatures (Freeze/Thaw)

- High Wind Environments

- Hail Prone Regions

- Fire Prone Regions

Building Locations

U Panel is suitable for use on the following building locations:

- Roofing

- Siding

- Ceiling

- Soffit

- Interiors

Finished Coverage

- Roof: 36″ Finished Coverage

- Wall: 36″ Finished Coverage

Panel Variations

- PBR Panel is not currently offered with variations differing from the original panel profile.

For custom panel designs, please contact a helpful team member

Panel Gauges

- Standard Thickness: 26 gauge steel

- Optional Thickness: 24 gauge steel*

- Optional Thickness: 29 gauge steel*

*Longer lead times may apply

Fastener Options

- Exposed, through-fastened screws

Panel Length

PBR Panel is not available for on-site roll-forming. The max panel length is determined by the length of the trailer which varies depending on state.

- Max Length, Texas: 53′ panels

Contact your helpful team member for max lengths in other states.

Rib Height(s)

- 1.25″ Rib Height

Recommended Roof Slope

Minimum slope varies based on potential for ice & snow build up:

- No risk of ice & snow: 0.5:12 w/ mastic

- Potential risk of ice & snow: 2:12 w/ mastic

Paint Warranties

- PVDF – 40 year

- SMP – 40 year

- Acrylic – 40 year

- Bare Galvalume – 25 year

Panel Documentation

Trim Details

Specification Guide

Installation Guide

Looking for Additional Information?

Still have a question about this or other panels? Check out our range of articles on metal roofing, siding, coils & flats, and other industry information below.